Scaling Aerospace Operations: Custom Vs Standard Aviation Software Development

Aviation software development faces a critical challenge, with airlines reporting that over 50% of their IT budgets go to maintaining legacy systems rather than driving innovation. Many airlines still rely on highly sensitive IT infrastructure that has been in place for 20 to 50 years, creating significant operational limitations in an increasingly digital world.

In fact, according to industry experts, “containing cost growth while remaining safe, secure and reliable” represents a top IT challenge for airlines today. This reality places aerospace and defense organizations at a crossroads when selecting software solutions. Standard, off-the-shelf products offer immediate deployment but often lack the flexibility required for mission-critical operations. Conversely, custom aviation software development provides tailored workflows and specialized functionality that can transform operational efficiency. With the global enterprise software development market projected to grow at a CAGR of 11.5% over the next five years, organizations must carefully evaluate their approach to technology investment.

Additionally, enterprise software frequently manages extremely valuable and sensitive data that requires protection through advanced technological methods. For aerospace operations specifically, scalable ERP solutions have become indispensable tools that ensure regulatory compliance, manage complex supply chains, and streamline project management.

Legacy Software Constraints in Aerospace Operations

Despite growing investments in innovation, aerospace operations continue to be hampered by aging IT infrastructure. Recent IATA data reveals that 80% of airlines now report legacy IT as a significant roadblock, up from 65% in 2019. These outdated systems create substantial operational constraints that limit efficiency and increase costs across the industry.

High Maintenance Costs of Monolithic Systems

The financial burden of maintaining legacy aviation systems has reached critical levels. System downtime from failed upgrades costs airlines up to $400,000 per hour, creating enormous financial pressure. Furthermore, nearly half of digital upgrades fail due to poor integration between old and new technologies, compounding these expenses.

Operating and support costs for aircraft maintenance have shifted dramatically, with maintenance becoming a larger portion of total costs—increasing by $1.2 billion since fiscal year 2011. Legacy systems typically exhibit monolithic architectures with tightly coupled hardware and software, making them expensive to maintain and difficult to modernize.

As aircraft age, they require more extensive maintenance due to component wear, technological obsolescence, and increased repair complexity. This directly translates into longer ground times and higher operational costs for aerospace organizations. Consequently, airlines face a double burden: increasing costs to maintain both aging aircraft and the outdated software systems that support them.

Data Silos and Integration Barriers in Legacy Platforms

Legacy aviation systems were engineered to handle singular tasks without foresight into today’s demand for cross-functional data sharing. This fundamental design limitation creates significant operational inefficiencies. A 2024 report on Baggage IT Insights found that 46% of airports cite “integration challenges with legacy systems” as a significant hurdle.

The core challenge is compatibility—legacy systems were never built to communicate with modern platforms like AI, IoT, or cloud-based tools. These systems typically operate in isolation, impeding the seamless flow of data across departments and stakeholders. Older systems often use outdated communication protocols, making integration with modern aviation software development solutions cumbersome or outright impossible.

Integration challenges manifest in several critical ways:

- System interoperability issues with modern applications

- Limited or non-existent APIs for connecting with newer systems

- Security vulnerabilities when attempting to bridge old and new technologies

- Rigid architectures that resist modification

These limitations prevent aerospace organizations from implementing modern aviation data management systems that could otherwise drive operational efficiency.

Developer Shortages for COBOL and Mainframe Systems

The technical debt crisis is further exacerbated by a severe talent shortage. More than 200 billion lines of COBOL code remain in production across industries, with that number growing each year. Yet finding qualified personnel to maintain these systems presents a significant challenge.

Industry research reveals that 71% of mainframe teams are currently understaffed, 54% report being underfunded, and 93% say finding qualified mainframe talent is “moderately to extremely challenging”. This skills gap is particularly acute in aviation software development, where specialized knowledge of both aerospace operations and legacy programming is required.

The demographic shift in the workforce compounds this problem. As veteran mainframe experts retire, a knowledge vacuum is forming. Organizations struggle to find replacements with expertise in COBOL and other legacy programming languages, especially as younger developers gravitate toward more modern technologies.

Despite these challenges, mainframes remain critical infrastructure—handling 70% of global financial transactions and supporting essential aerospace operations. This creates a strategic dilemma for aviation companies: continue investing in maintaining increasingly expensive legacy systems with a shrinking talent pool, or transition to modern custom aviation software development solutions designed for today’s operational requirements.

Standard Aviation Software: Benefits and Limitations

Standard aviation software packages offer pre-built solutions that can be implemented across aerospace operations with minimal configuration. These products promise “out-of-the-box” functionality for organizations seeking immediate operational capabilities without the delays typically associated with custom development. However, a thorough examination reveals significant tradeoffs that aerospace decision-makers must consider.

Predefined Modules and Faster Deployment

Modular aviation software systems provide a structured approach to implementing technical solutions. Products like SAM (Safety and Airworthiness Management) offer module-based architectures that allow organizations to select only the components they need, avoiding payment for unnecessary functionality. Similarly, AirTOP presents a scalable framework where users can begin with core modules like Airside Aircraft and gradually expand their capabilities as operational needs evolve.

The primary advantages of standardized solutions include:

- Accelerated implementation timelines—some platforms promise deployment in as little as eight weeks

- Regulatory alignment through standardized processes that maintain consistent compliance

- Operational uniformity that streamlines staff training and reduces procedural errors

- Enhanced data integrity through uniform entry and management practices

Moreover, standard aviation software often includes configurable templates that provide starting points for implementation. These pre-built frameworks enable organizations to establish operational baselines quickly, subsequently fine-tuning them to match specific Approved Maintenance Plans.

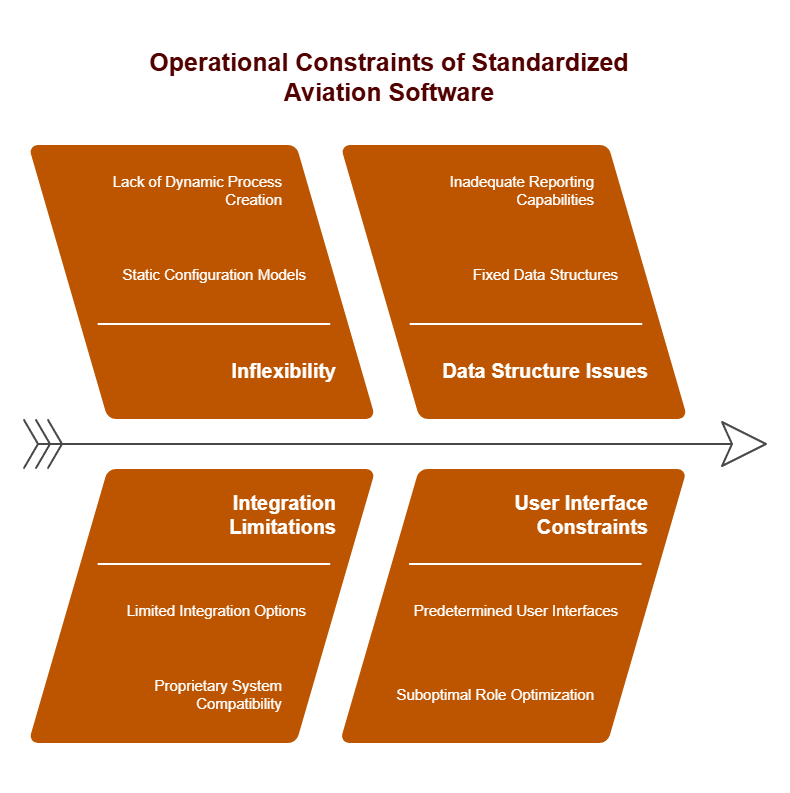

Lack of Flexibility for Mission-Critical Customization

Although standardized solutions offer rapid deployment benefits, they frequently impose significant operational constraints. Generic aviation software typically covers only basic operational needs yet fails to address industry-specific challenges that require specialized functionality. This limitation becomes increasingly problematic as organizations scale their operations or encounter unique operational scenarios.

Throughout the past decade, the full lifecycle costs of customized systems have prompted many original equipment manufacturers to shift toward Commercial Off-The-Shelf (COTS) solutions. Nevertheless, these standardized platforms often utilize static configuration models where system parameters must be defined before deployment. Once applications are initiated, the rigid architecture prevents dynamic creation of new processes or objects—a design choice that enhances determinism for safety-critical applications at the expense of operational adaptability.

This inflexibility manifests in several critical ways:

- Limited capability to adapt to unique business models and operational workflows

- Restricted integration options with proprietary or specialized systems

- Fixed data structures that may not accommodate organization-specific reporting needs

- Predetermined user interfaces that cannot be fully optimized for specialized roles

Challenges in Meeting AS9100 and FAA Compliance

Aerospace software must adhere to extraordinarily rigorous compliance standards. AS9100, the globally recognized quality management system for aerospace and defense, extends beyond ISO 9001 requirements to include stringent specifications for product safety, risk management, counterfeit parts prevention, and configuration management. For organizations seeking partnerships with major OEMs like Boeing, Airbus, or Lockheed Martin, AS9100 certification has become non-negotiable.

Additionally, flight-critical software must comply with FAA regulations through DO-178C, the de facto standard for demonstrating airworthiness compliance. This framework defines five criticality levels based on potential failure impacts, ranging from “Catastrophic” (potentially causing deaths) to “No Effect” (no impact on safety).

Notably, the cost of developing software in compliance with these standards remains exceptionally high. Standard aviation software often struggles to accommodate the complex compliance requirements specific to each organization’s operational context. The high-risk nature of aerospace operations demands customized safety protocols that generic solutions rarely provide comprehensively.

In essence, although standard aviation software offers immediate operational capabilities, aerospace organizations frequently discover that these solutions lack the flexibility, customization capacity, and compliance depth required for mission-critical applications. This realization typically leads forward-thinking organizations to explore custom aviation software development alternatives that can be precisely tailored to their operational requirements.

Custom Aviation Software Development: Strategic Advantages

Custom software development offers aerospace organizations unparalleled advantages that address the specific pain points of aviation operations. Unlike generic solutions, bespoke aviation software provides adaptability and precision essential for meeting the complex demands of aircraft manufacturing, maintenance, and supply chain management. First and foremost, custom solutions ensure that every aspect of the software aligns with the organization’s unique operational requirements and long-term strategies.

Tailored Workflows for Aircraft Manufacturing and MRO

Aircraft manufacturing and Maintenance, Repair, and Overhaul (MRO) operations demand precision workflows that generic software simply cannot provide. Custom aviation software development enables organizations to consolidate excessive, disconnected systems into one integrated platform, eliminating waste and reducing error potential. This integration is crucial as aviation companies report that inefficient communication between departments such as maintenance, operations, and engineering leads to costly delays.

Custom MRO solutions offer significant operational improvements through:

- Digital work instructions that allow aircraft technicians to access intuitive guidance lineside, record data in real-time, and report nonconformances directly from the step where they’re discovered

- Comprehensive change management and history tracking that streamline audits and ensure compliance throughout refurbishment and upgrade activities

- Nonconformance management systems that monitor, control, and track every defective component across the organization, reducing safety risks caused by human errors

These tailored workflows address the industry-specific challenges that standard solutions typically overlook. Indeed, the distinction between custom airline software and generic solutions is stark—custom development aligns precisely with unique business models and operational needs.

Real-Time Data Visibility in Aviation Supply Chain Software

In aviation, supply chains have never been more challenging to manage. Data-driven software platforms transform aviation supply chain management by providing real-time tracking of parts and materials, granting manufacturers comprehensive visibility across their entire supply chain.

This enhanced visibility delivers critical operational benefits:

Predictive analytics can anticipate demand fluctuations and potential supply issues before they materialize, enabling proactive problem-solving rather than reactive crisis management. Accordingly, machine learning models excel at identifying patterns in supplier performance, helping detect potential bottlenecks or unreliable suppliers in advance. This early warning capability empowers manufacturers to swiftly adjust production schedules and sourcing strategies.

As advanced analytics platforms examine historical data, market trends, and external factors, they generate accurate forecasts for specific parts demand—optimizing inventory management and reducing risks of costly stockouts or excess inventory. This level of precision is unattainable with standard solutions that lack the flexibility to incorporate organization-specific data models and analytical frameworks.

Integration with Aircraft Materials Tracking Systems

Custom aviation software excels at controlling multisite and multilevel as-built BOM traceability, enabling organizations to quickly identify and act on problematic materials. This capability is essential for compliance with stringent aviation quality standards such as ISO 9001 and AS9100 certifications and FAA requirements.

The integration benefits extend to aircraft inventory management, where custom solutions provide:

Real-time alerts and automated inventory registries that eliminate manual data entry errorsDetailed purchase order tracking that monitors vendor activities and manages stock from order placement to receiptPredictive maintenance capabilities that analyze aircraft systems data to anticipate issues before they cause downtime

These integrated tracking solutions effectively address the data silos that hamper standard aviation software implementations. In essence, they create a centralized hub for information sharing between all stakeholders, enabling suppliers, logistics providers, and airlines to collaborate quickly and ensure timely deliveries.

Custom aviation software development offers unmatched flexibility and precision for aerospace operations facing evolving challenges. By tailoring solutions to specific operational workflows, enabling real-time supply chain visibility, and seamlessly integrating with materials tracking systems, these bespoke solutions drive efficiency gains that off-the-shelf products simply cannot match.

Technology Enablers for Scalable Custom Solutions

Modern aviation software development has evolved beyond traditional methodologies to embrace cutting-edge technologies that enable truly scalable solutions. For aerospace organizations, these technological foundations are essential for building systems that can adapt to changing operational demands without sacrificing performance or security.

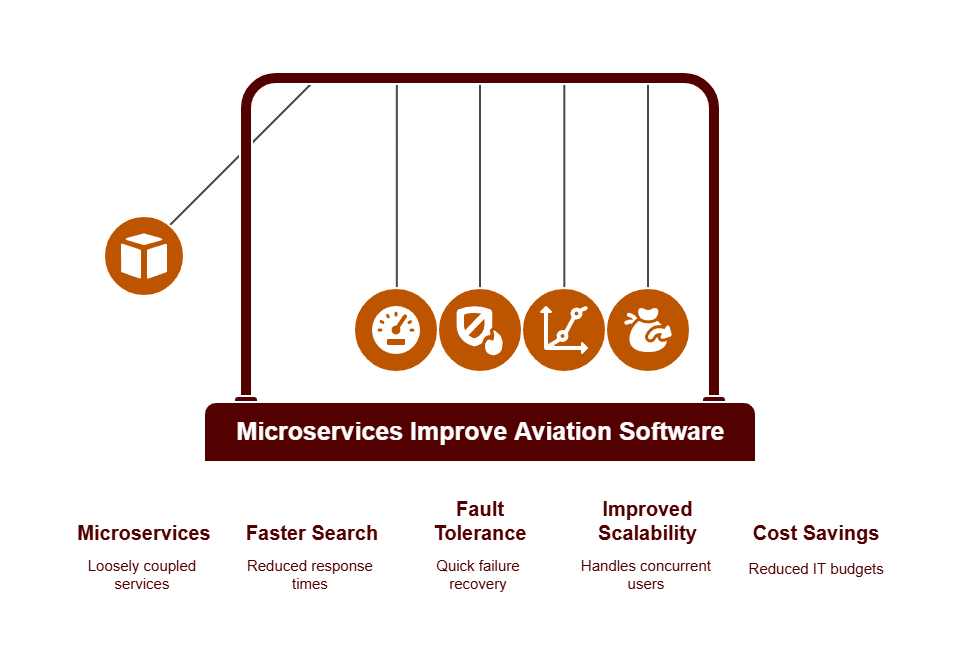

Microservices Architecture for Modular Scalability

The shift from monolithic systems to microservices architecture represents a fundamental advancement in aviation software engineering. By breaking down complex applications into smaller, independent services, aerospace organizations gain unprecedented flexibility and efficiency. This approach addresses a critical pain point—ITS, a travel application provider, discovered that monolithic architectures became increasingly complex and difficult to scale as demand grew.

After restructuring their air travel application into microservices, ITS achieved:

- Significantly accelerated search speeds with response times reduced from 480ms to 250ms

- Enhanced fault tolerance with recovery from microservice failures in under 200ms

- Improved scalability that handled up to 10,000 concurrent users while maintaining 590ms average response time

First of all, microservices architecture intrinsically breaks down tightly coupled applications into loosely bound, context-specific services—making systems more flexible and responsive to change. As a result, aviation companies have reported year-over-year cost savings exceeding 20% on enterprise IT budgets through API/microservices adoption.

Cloud-Native Aviation Applications with Multi-Cloud Support

Cloud-native aviation applications represent the next frontier for aerospace IT infrastructure. GE Aviation’s transition to a fully AWS cloud-native design demonstrates this evolution—moving from traditional on-premises data footprints to a serverless architecture with Amazon S3 as the foundational data lake storage platform.

In conjunction with this trend, the aviation industry is increasingly embracing multi-cloud strategies. To illustrate, Lufthansa Systems recently partnered with Google Cloud to advance multi-cloud support for airlines, whereas SITA integrated with Alkira to enhance multi-cloud connectivity for aviation. This approach is consistent with broader industry trends, as 81% of companies are adopting multi-cloud strategies.

The multi-cloud approach delivers several key advantages:

- Increased agility through network automation that responds to changes in real-time

- Enhanced visibility via centralized portals that provide control of resources across cloud environments

- Improved security through comprehensive frameworks incorporating next-generation firewall capabilities

AI and ML for Predictive Maintenance and Route Optimization

Artificial intelligence and machine learning are transforming two critical aspects of aviation operations: maintenance and flight path optimization. On the maintenance front, predictive analytics enabled by AI can anticipate equipment failures before they occur—with one mining company projecting at least a 35% reduction in troubleshooting time once fully implemented.

Simultaneously, AI is optimizing flight routes and reducing environmental impact. Alaska Airlines’ partnership with Air Space Intelligence (ASI) demonstrates this potential—their Flyways AI Platform analyzes weather patterns, winds, turbulence, airspace constraints, and traffic volume to generate optimized route recommendations. Between January and September 2022, this implementation saved Alaska Airlines an average of 2.7 minutes per flight, preventing 6,866 metric tons of carbon dioxide emissions.

CyberProcess™ Framework for Secure Aviation Software Engineering

Security remains paramount in aviation software development. CyberMedics’ proprietary CyberProcess™ Framework addresses this concern by integrating cybersecurity throughout the entire software development lifecycle—not merely as an afterthought. This approach aligns with aviation industry needs for comprehensive security by design.

This framework enables aerospace organizations to achieve uncompromising security without sacrificing agility—combining the speed advantages of microservices with the safety requirements of highly regulated environments.

Compliance and Security in Custom Aerospace Software

Regulatory compliance represents a critical cornerstone for aerospace operations. Custom aviation software development stands apart from standard solutions through its ability to address complex regulatory requirements from inception, thereby eliminating costly retrofits and compliance gaps.

Built-in Support for AS9100 and ITAR Requirements

Custom aerospace software excels at embedding AS9100 requirements directly into system architecture. AS9100, the internationally recognized aerospace quality management system standard, extends beyond ISO 9001 to address aerospace-specific requirements for product safety, risk management, counterfeit parts prevention, and configuration management. This certification has become essential for suppliers seeking to work with major aerospace OEMs like Boeing, Airbus, and Lockheed Martin.

Custom solutions also provide comprehensive support for International Traffic in Arms Regulations (ITAR). These regulations govern the manufacture, sale, and distribution of defense and space-related articles defined in the United States Munitions List (USML). For aerospace organizations, ITAR compliance requires maintaining restricted access systems where controlled technical data remains inaccessible to unauthorized foreign nationals.

Cybersecurity by Design in Aviation Software Lifecycle Management

The aviation industry faces unique cybersecurity challenges as aircraft systems become increasingly connected. Effective protection requires a multilayered approach ensuring that a successful attack on one system layer cannot compromise others or lead to loss of safety, security, or critical functions.

Custom aviation software development incorporates security throughout the entire development lifecycle rather than as an afterthought. This “security by design” approach considers security objectives from a system’s conception alongside traditional operational and safety requirements. The implementation includes:

- Comprehensive risk assessment processes

- Protection of critical infrastructure components

- Fault-tolerant system architecture

- Continuous monitoring capabilities

Audit-Ready Documentation and Traceability Features

Traceability remains fundamental to aerospace compliance. In highly regulated environments, organizations must understand risk associated with every system change – it’s not merely good practice but a legal requirement for onboard avionics platforms.

Custom software solutions integrate documentation verticals that provide unbroken traceability from requirements to implementation. During audits, aerospace organizations must demonstrate why changes were made, what code was modified, whether the code was properly reviewed, and which production systems utilize the modified code.

Digital traceability features in custom solutions include electronic signatures, automated document versioning, controlled digital change logs, and as-built Bill of Materials management. These capabilities ensure every repair, replacement, and inspection action is logged and audit-ready.

Beyond compliance, these traceability features yield operational benefits including faster troubleshooting, reduced waste, and improved overall efficiency – creating a sustainable competitive advantage beyond merely meeting regulatory requirements.

Choosing the Right Aviation Software Development Partner

Selecting the right development partner represents perhaps the most crucial decision in the aviation software acquisition process. With aerospace systems becoming increasingly complex, organizations must thoroughly evaluate potential vendors against industry-specific benchmarks before committing to long-term partnerships.

Evaluation Criteria for Aviation Software Development Companies

Effective assessment of aviation software development companies requires examination of several critical factors. First, certification adherence serves as a foundational qualifier—look for partners with ISO 9001-2015 and AS9100D certifications that demonstrate commitment to quality and compliance with industry regulations. Experience within aerospace specifically matters greatly, as general software development expertise rarely translates fully to aviation’s unique requirements.

Development methodology represents another essential consideration. Companies employing DevSecOps practices embed security at every development stage rather than treating it as an afterthought. This approach ensures that best cybersecurity practices influence every step of development, fundamentally strengthening the final product.

Why CyberMedics is Trusted by Aerospace and Defense Leaders

CyberMedics stands apart through its specialized expertise in aerospace and defense software. Their engineering staff brings significant aviation experience, with team members possessing backgrounds across various technical disciplines. This domain knowledge enables them to deliver solutions that address industry-specific challenges that generalist developers often miss.

The company’s proprietary CyberProcess™ Framework integrates cybersecurity throughout the entire software development lifecycle—not merely as an afterthought. This methodology aligns perfectly with the aviation industry’s stringent security requirements.

Case Example: CyberMedics’ Role in Aviation Systems Integration

CyberMedics has effectively transformed traditional serial software engineering processes—similar to waterfall methods—into agile, iterative approaches for aircraft systems integration. This transition primarily benefits aerospace organizations through faster delivery cycles and enhanced adaptability.

By implementing agile methodologies, CyberMedics delivers incremental value-added design rather than waiting for complete system integration—a fundamental shift from traditional aviation software development approaches. Their focus on forming long-term relationships—averaging three years with clients—fosters deeper understanding of operational requirements and enables truly customized solutions.

Conclusion

The aerospace industry faces a critical inflection point as legacy systems continue to strain operational budgets and limit innovation potential. Throughout this analysis, we have seen how standard aviation software offers immediate deployment advantages but ultimately falls short in addressing the complex, mission-critical requirements that define modern aerospace operations. Custom aviation software development, conversely, provides the precision, flexibility, and compliance capabilities essential for organizations seeking sustainable competitive advantage.

As aerospace operations scale, the limitations of generic solutions become increasingly apparent. The tailored workflows possible through custom development directly address the unique challenges of aircraft manufacturing and MRO processes. Additionally, real-time visibility across aviation supply chains and seamless integration with materials tracking systems create operational efficiencies impossible with standard software packages.

Technology enablers such as microservices architecture, cloud-native applications, and AI-powered analytics have fundamentally transformed what custom aviation software can deliver. These innovations allow aerospace organizations to break free from monolithic legacy constraints while maintaining rigorous compliance with AS9100 and ITAR requirements. The security-by-design approach embedded within custom solutions also ensures protection against evolving cybersecurity threats that continue to target the aerospace sector.

Selecting the right development partner remains perhaps the most consequential decision in this process. Organizations that choose partners with deep aerospace domain expertise, proven compliance credentials, and innovative technical capabilities position themselves for long-term success. The transition from legacy systems to modern, custom-built solutions requires not just technical expertise but a fundamental understanding of aerospace operations that only specialized partners can provide.

The aerospace industry will continue facing unprecedented challenges – from complex regulatory requirements to increasing sustainability demands. Therefore, forward-thinking organizations must evaluate whether their current aviation software infrastructure can support their long-term strategic objectives or if custom solutions would better enable operational excellence and innovation. The choice between standard and custom aviation software ultimately represents a decision between accepting operational limitations or embracing the transformative potential of purpose-built technology tailored precisely to aerospace requirements.

Key Takeaways

The aerospace industry stands at a critical crossroads between legacy constraints and modern innovation, where the choice between standard and custom aviation software determines operational success and competitive advantage.

- Legacy systems drain resources: Over 50% of airline IT budgets maintain outdated systems, with downtime costing up to $400,000 per hour and 46% of airports citing integration challenges as major hurdles.

- Standard software offers speed but lacks flexibility: While off-the-shelf solutions enable rapid 8-week deployments, they cannot accommodate mission-critical customizations or unique compliance requirements like AS9100 and ITAR.

- Custom solutions deliver strategic advantages: Tailored aviation software provides real-time supply chain visibility, integrated materials tracking, and workflows specifically designed for aircraft manufacturing and MRO operations.

- Modern technology enables scalable custom development: Microservices architecture, cloud-native applications, and AI-powered predictive maintenance transform operational efficiency while maintaining rigorous security standards.

- Compliance and security require specialized expertise: Custom development embeds AS9100 and cybersecurity requirements from inception, providing audit-ready documentation and traceability that standard solutions cannot match.

The decision between standard and custom aviation software ultimately determines whether organizations accept operational limitations or embrace transformative technology precisely tailored to aerospace requirements. With 81% of companies adopting multi-cloud strategies and AI delivering measurable results like Alaska Airlines’ 6,866 metric tons of carbon savings, custom solutions represent the path forward for aerospace organizations seeking sustainable competitive advantage.

FAQs

Q1. What are the main differences between standard and custom aviation software? Standard aviation software offers faster deployment but lacks flexibility, while custom solutions provide tailored workflows, real-time data visibility, and better integration with existing systems, addressing specific operational needs of aerospace organizations.

Q2. How does custom aviation software improve compliance with industry regulations? Custom aviation software can embed AS9100 and ITAR requirements directly into the system architecture, providing built-in compliance features, audit-ready documentation, and comprehensive traceability that standard solutions often struggle to match.

Q3. What technological advancements are enabling more scalable custom aviation software? Microservices architecture, cloud-native applications with multi-cloud support, and AI/ML integration for predictive maintenance and route optimization are key technologies enabling more scalable and efficient custom aviation software solutions.

Q4. Why is cybersecurity crucial in aviation software development? Cybersecurity is critical in aviation due to the increasing connectivity of aircraft systems. Custom solutions incorporate a “security by design” approach, integrating protection measures throughout the entire software development lifecycle to safeguard against evolving threats.

Q5. How can aerospace organizations choose the right software development partner? Organizations should evaluate potential partners based on their industry-specific certifications (like ISO 9001-2015 and AS9100D), experience in aerospace, development methodologies (such as DevSecOps), and ability to provide long-term support and understand unique operational requirements.